LEAD is accelerating digital transformation in manufacturing by combining intelligent automation with advanced module assembly processes. Through its Auto Module Stacking System, LEAD helps manufacturers optimize production using standalone machines designed for precision tasks like testing, cleaning, glueing, splicing, and insulation film application. This digital-first approach increases efficiency while reducing manual labor and errors.

Automated Module Stacking Enhances Manufacturing Intelligence

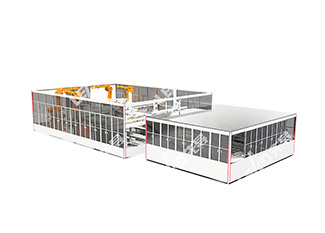

Digital transformation in manufacturing requires more than just digitization—it demands intelligent systems that work in harmony. LEAD’s Auto Module Stacking System allows flexible stacking in either single or multiple rows, guided by established grouping sequences. These smart systems bring greater adaptability and accuracy to battery module production.

Standalone Machines Empower Smart Production

Each standalone unit in LEAD’s system plays a vital role in the digital transformation in manufacturing. Machines are assigned specific tasks such as end plate installation or taping, enabling better task division and streamlined workflows. This modular structure supports scalable production without compromising quality or performance.

Data-Driven Control and Real-Time Monitoring

By integrating data collection and control systems, LEAD transforms module assembly into a digitally connected process. Operators can monitor operations in real time, adjust settings remotely, and analyze performance metrics instantly. This integration is a core benefit of digital transformation in manufacturing and sets a new standard for operational visibility.

Redefining Competitive Manufacturing with LEAD

LEAD’s approach to digital transformation in manufacturing empowers businesses to achieve smarter, faster, and more cost-effective production. The Auto Module Stacking System represents a major step toward intelligent factories—where every step is optimized by data and automation.

Conclusion

Through innovation and precision, LEAD turns digital transformation in manufacturing into a practical reality for forward-looking enterprises.